Elevator maintenance rules

Date: 2024-07-15 Categories: Industry News Hits: 260

In order to ensure the safe operation of the elevator, it is necessary to carry out regular maintenance, inspection and repair of the elevator. The elevator manager and the electrician on duty in the elevator room are responsible for emergency maintenance work when the elevator fails. The head of the company's engineering department is responsible for the organization and monitoring of elevator failure repairs and is responsible for establishing an elevator maintenance management system. The elevator maintenance management system mainly includes:

1. Monthly maintenance system Fill out the "Elevator Monthly Maintenance Record" after the inspection is completed. Elevator monthly maintenance record Maintenance items Cleaning inspection and investigation record Partial record of bad situations and treatment results Machine room

1. Clean the traction wheel

2. Check the speed limiter and electrical contacts

3. Check the wear of the brake shoe

4. Check the layer selector

5. Clean the electromechanical contacts of the control cabinet, the contactors, relay resistors, fuselages and wells

(1) Check the battery and storage battery

(2) Check, clean and oil the internal and external door couplings

(3) Check and clean the internal and external door wheels, limit wheels, external door closers and rails

(4) Clean the internal and external door locks and the door interlock switches and their contacts

(5) Check the door interlock wiring

6. Assembly of the joint plate

7. Check various switch contacts

8. Clean and oil the steel belt, check the steel belt switch

9. Check, clean and oil the equipment at the bottom of the speed limit wire test well.

Maintenance personnel and verifiers inspect the main equipment in the machine room. After the inspection is completed, fill in the "Elevator Quarterly Maintenance Record". Elevator quarterly maintenance record, maintenance items cleaning inspection investigation record bad situation partial record and treatment results machine room

1. Motor cooling fan oil filling

2. Main power switch

3. Clean the control panel and signal panel, tighten the lead screws, and check the inside of the machine body and the well 1 door machine assembly box

2. Check the inside of the door machine motor, resistor box, and contact box

3. Check the door machine gear box, connecting rod, chain, and belt

4. Check the gap between the rail assembly and the rail

5. Check the wear, cleanliness, and tension balance of the main steel wire

6. Check and clean the car fan

7. Check and clean the oil level of the pit buffer and the friction device Maintenance personnel and verifiers

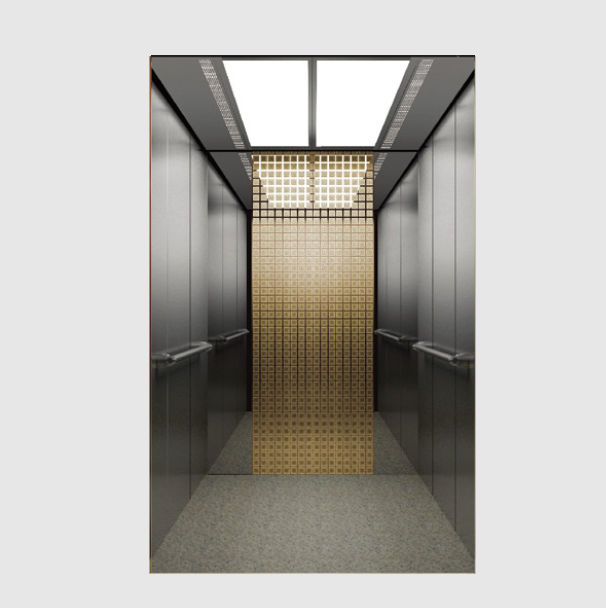

Glass SA-K002

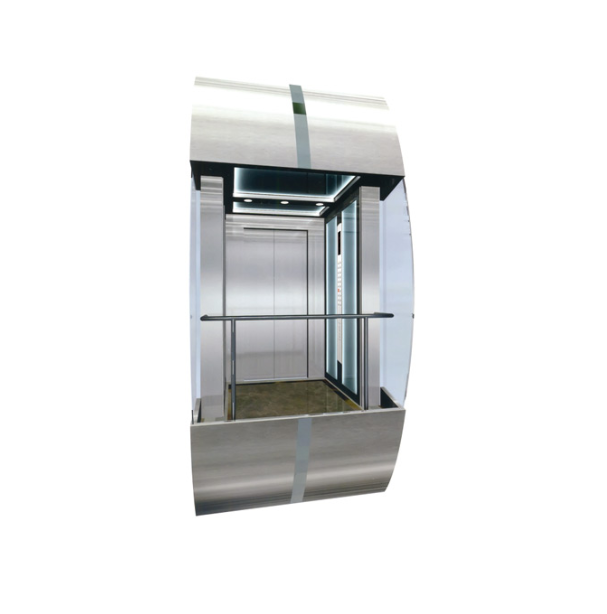

Glass SA-K002  Fashion SA-K007

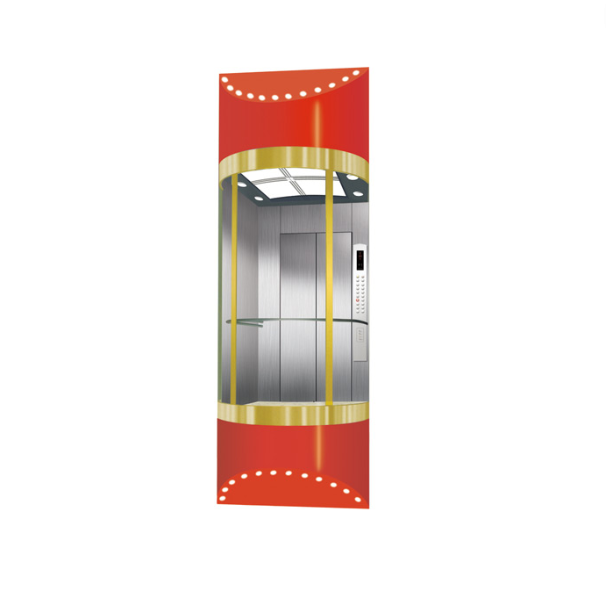

Fashion SA-K007  SA-G005

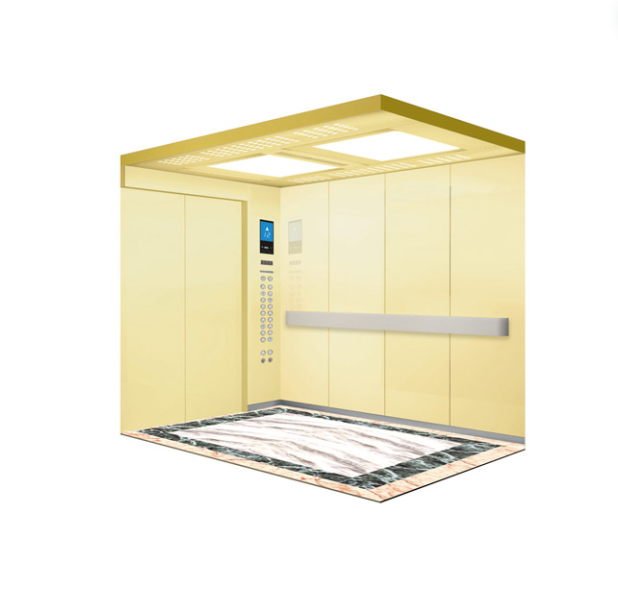

SA-G005  SA-G004

SA-G004  SA-G003

SA-G003  SA-G002

SA-G002  SA-G001

SA-G001  SA-B002

SA-B002  SA-B001

SA-B001  SA-HJ02

SA-HJ02  SA-HJ01

SA-HJ01  SA-Y005

SA-Y005  SA-Y004

SA-Y004  SA-Y003

SA-Y003  SA-Y001

SA-Y001